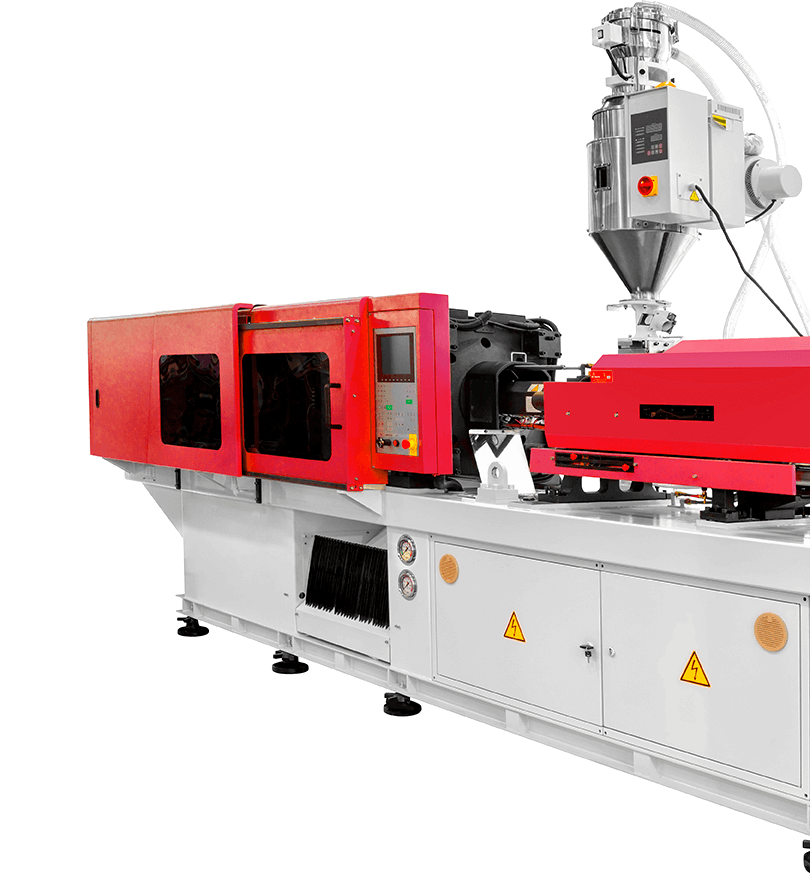

PPI helps customers to select the molding process that best fit their applications, budget and production life span. This includes engineering design, CNC machining, purchasing, assembly, short-long run production, complex assembly, painting, testing, packaging and shipping.