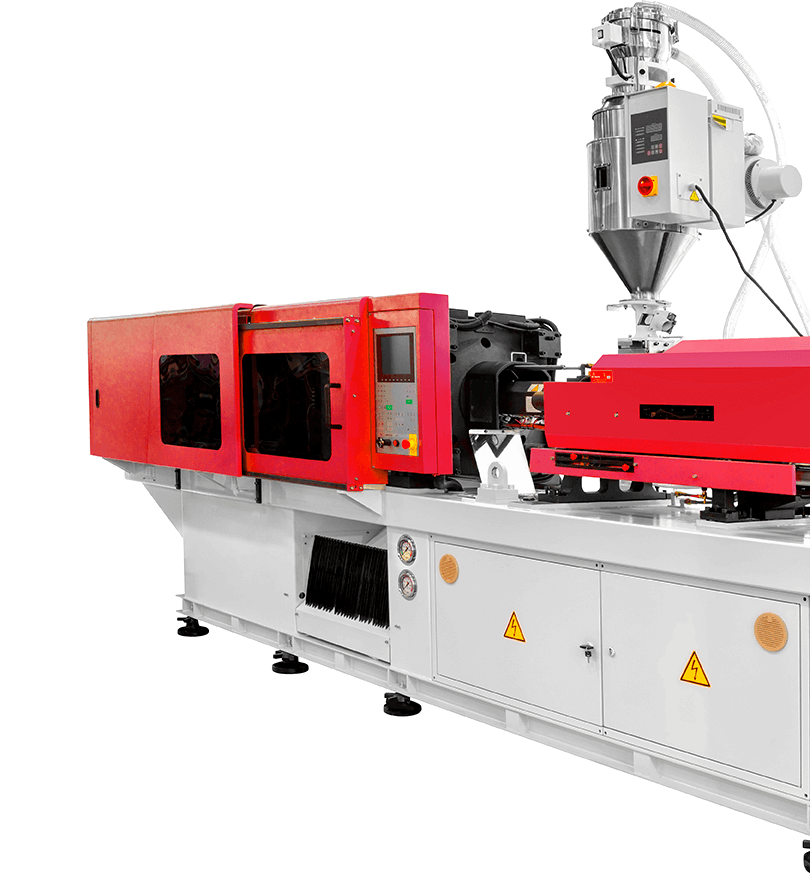

Structural foam molding is a low-pressure injection molding process that utilizes a chemical blowing agent or nitrogen gas. Structural foam molding is an extension of the standard injection molding process, but operates under the theory of delivering a ‘short-shot’ into the mold. Parts molded in structural foam are typically larger, have a much higher strength-to-weight ratio, and are virtually free of stress and sink marks.

Due to the process, solid skins are formed against the walls of the mold, while the interior of the part remains foamed, which allows a typical reduction in part weight by 5-20%. Structural foam parts are excellent candidates for various paint and shielding media.